A Guide to Green Energy Adoption for Transit Agencies Chapter 6: Supporting Deployments of Green Energy and Zero-Emission Vehicles

- Date: February 16, 2022

Jump to section

Deploying new technologies like zero-emission vehicles and green power systems into ongoing operations requires planning, coordination, training, and ongoing monitoring for the deployments to be successful. This chapter of the Green Energy Guide focuses on pre-deployment and post- deployment activities that transit agencies should consider once they procure zero-emission vehicles. These activities include inspections, testing, and staff training for both operations and safety. While the activities discussed focus on zero-emission vehicle deployments, considerations for integrating green power systems are discussed as well. Both zero-emission vehicles and on-site green power will present new operational and new safety considerations for transit agencies.

Many of the activities discussed in this chapter are dependent on terms agreed upon in the procurement contract with a zero-emission vehicle (ZEV) original equipment manufacturer (OEM). Before deploying new zero-emission vehicles, both pre- and post-delivery inspections and acceptance testing of the vehicles must be completed to ensure that the vehicles are built and perform according to the contractual and performance requirements that were agreed upon with the OEM in the procurement and contracting process. The procurement contract should also contain stipulations for the amount of training to be provided by the OEM. Bus manufacturers are intimately familiar with their products and can provide agency staff with the necessary knowledge to operate and maintain the ZEVs safely, efficiently, and in line with best practices. Agency staff will need to be trained on details of the vehicles and supporting systems so that they can perform actions after the buses are deployed, such as maintenance of the vehicles and tracking of certain key performance indicators. These activities are discussed in more detail in the following sections.

Pre-Deployment Considerations

Successfully deploying ZEVs into transit service requires the completion of a few pre- deployment steps: pre-delivery inspections, post-delivery inspections, and acceptance testing. Completing these activities will help ensure that vehicles meet specified performance requirements before an agency fully accepts the vehicle delivery and deploys the vehicles into service.

Pre-delivery Inspections

Pre-delivery inspections ensure that vehicles meet the specifications included in the contract before the vehicle ever leaves the OEM’s facility. This type of inspection is generally not a requirement for projects using federal funds unless a bus order is for more than 10 buses. If a deployment project is using federal funds and deploying more than 10 buses, the Federal Transit Administration (FTA) requires that a resident inspector conduct inspections of the vehicles at the OEM’s facility (Federal Transit Administration, 2016). The resident inspector must visually inspect the vehicles and conduct road tests. Regardless of the federal grant rules, industry best practice is to have a vehicle inspector at the OEM facility, specifically one who has knowledge of electric drive vehicles and high-voltage systems, to perform inspections of the vehicle before it leaves the OEM’s facility. There are zero-emission bus (ZEB) experts available that can be contracted in order to perform such inspections, if needed. In-house inspectors could also be educated by a ZEB expert on the electric drive technology through an assisted inspection. These inspections help to identify any deviations from the contracted specifications or any defects in the product so that the OEM can address any issues before the vehicles are delivered to the agency.

Post-delivery Inspections

Once the vehicles arrive at the transit agency’s facility, post-delivery inspections confirm that the vehicles were not damaged during the delivery process. If zero-emission technology is new to an agency’s fleet, the agency’s maintenance staff may need assistance in conducting a post- delivery inspection.

Prior to delivery, transit agencies should ask the vehicle OEM to provide training on the new bus components so that agency staff can more effectively conduct an inspection. Naturally, it is important to arrange this training with the vehicle OEM before the vehicles arrive, so that the OEM can come prepared to provide that training. Agency staff should also make sure they are aware of any of the specific hazards unique to zero-emission vehicles and associated infrastructure, such as high-voltage cables and battery-specific fire hazards. If any issues are noticed during the post-delivery inspection, the transit agency should communicate those issues with the bus OEM. All items should be addressed to the agency’s satisfaction before an agency officially accepts the vehicles. Post-delivery inspections are especially important for zero- emission vehicles. ZEVs are transported from the OEM to the agency’s facility, unlike new conventionally fueled vehicles that are driven from the OEM to the customer. As such, ZEVs spend less time on the roads before delivery and therefore there is less time to identify potential issues with the vehicles before they arrive at the agency.

Acceptance Testing

Acceptance testing is the process of testing the performance and functionality of the buses and fueling infrastructure to ensure that the contractual requirements specific to operations are met. Acceptance testing can occur in conjunction with or after the post-delivery inspections. The fueling infrastructure and any facility upgrades must be completed before acceptance testing in conducted. As such, agencies intending to install on-site green energy infrastructure along with new ZEB deployments should review their project schedules carefully to ensure that all necessary infrastructure is in place before post-delivery inspections and acceptance testing of the vehicles occur. The U.S. Department of Energy suggests accepting PV solar systems after the system has proven to operate for ten continuous days at energy and power production levels congruous with the PV manufacturer’s estimated energy production (Robinson, 2020).

Agencies should ensure there is contractual language between the green energy system manufacturer and installer that specifies expected energy performance and regulatory and design specifications that must be met before accepting the technology.

Acceptance criteria is typically detailed in the final vehicle contracts, with specific criteria for both bus and infrastructure technologies. The criteria should cover performance standards that the vehicles must meet; standards for component functionality or cabin temperature in extreme weather conditions, and standards for uptime or the requirement that all systems function at the time of acceptance.

The time period for acceptance testing is an important detail to include in the contract terms along with the acceptance criteria itself. Two common ways to define acceptance periods in the contract are a specific period of continuous time (e.g. 40 hours) or a testing period (e.g. 15 to 30 days). Under the continuous time approach, the bus must operate in the specified time period without any issues. If an issue does arise, the clock resets and the acceptance period will extend until the conditions are met. The testing period approach allows the agency to test the bus in any way it sees fit for the number of days detailed in the contract. The contract terms should also clearly define the criteria that must be met and under what conditions to inform acceptance or non-acceptance of the vehicles.

Public Engagement

Public engagement should be considered at the outset of any zero-emission technology deployment project, even before procurement begins. It is important to work closely with local communities before, during, and after the transition process to ensure that community needs continue to be met by the transit service and new technologies. Effective public engagement can provide a platform for a successful deployment by ensuring that community buy-in and resources can be leveraged to overcome any deployment hiccups.

A key to building authentic broad-based community support for a green energy project or zero- emission bus deployment is to identify natural local partners at the very outset of the project.

Agencies should consider cultivating relationships with community-based organizations, local air quality groups, and/or local electric vehicle advocacy groups who can work with the transit agency to develop community outreach strategies and communicate local issues and interests back to the agency. Deploying initial zero-emission vehicles on routes with high ridership or high visibility in the community is one strategy to help advertise the use of zero-emission technology, especially if an agency intends to complete a full fleet transition in the future.

Most communities welcome the opportunity to breathe cleaner air and be on the forefront of transportation and energy technologies. By highlighting the environmental benefits and the agency’s commitment to maintaining transportation services for the community, agencies can garner support for the current project and possible future projects.

Training

Zero-emission vehicles pose different safety and operational considerations than conventional vehicles. Staff training is therefore a crucial part of a successful ZEV deployment, especially if it is the first deployment of the zero-emission technology for an agency. The contract between the agency and the bus OEM should detail the type and amount of training the bus OEM will provide, as well as requirements for aids, materials, tools, and diagnostic equipment. An agency should aim to have the training take place soon after the buses are delivered so that staff are adequately trained on safety and operations when the vehicles are deployed in revenue service. Adequate pre-deployment training does not preclude additional training after buses have been deployed.

Operations Training

Zero-emission vehicle technology functions differently than conventional internal combustion engine (ICE) vehicles. This statement may seem obvious on its face but there are important implications for operator training because of these differences. Small operational details, such as the dashboard displays, will differ in a zero-emission vehicle. For instance, rather than a fuel gauge, the dashboard in a battery electric bus will most likely have an indicator for the state of charge (SOC) of the battery with estimates on remaining operating time and estimated range remaining.

One of the most significant differences for operators is the braking mechanism. Zero-emission buses use regenerative braking as opposed to conventional friction braking. Regenerative braking technology takes the kinetic energy created during the braking action and converts it into electrical energy, which then gets stored in the vehicle’s battery and helps extend the vehicle’s range. As such, driving and braking behavior will affect the amount of energy captured; more energy is captured when drivers brake gradually versus slamming on the brakes (McIntosh, 2019). To properly prepare operators for ZEB service, the bus OEM should provide training on regenerative braking of the vehicles. Agency staff should test drive the vehicles to understand how driving habits can significantly affect the efficiency and performance of the zero-emission buses, including recommended levels of acceleration and deceleration.

Safety Training

All staff who operate or support zero-emission vehicles in any way should go through the proper safety training for the vehicles and their associated infrastructure. Agency staff familiar with fossil fuel safety procedures and precautions will need to be retrained to safely work with and around hydrogen or high-voltage batteries. The National Fire Protection Association’s (NFPA) website contains a collection of free Emergency Response Guides from multiple battery electric and fuel cell electric bus manufacturers such as Nova Bus, Proterra, GILLIG, BYD, and Van Hool Bus.

Local first responders should also be contacted and included in any OEM first responder safety training before the buses are placed in revenue service. First responders who are unfamiliar with zero-emission vehicles must learn to recognize the difference between a conventional bus and a zero-emission bus, as well as the difference between internal combustion engine fires and battery electric or hydrogen vehicle fires, so that appropriate response measures can be taken. The National Fire Protection Research Foundation produced a report that discusses best practices for emergency response procedures specifically for electric drive vehicle battery incidents, which is available for free on NFPA’s website.

Driver training should also include notable safety points. ZEBs produce much less noise than conventional internal combustion engine vehicles. Driver training should include a review of the risks that this silent operation presents to unaware or hearing-impaired pedestrians. The lack of noise may also pose issues in situations where it is not clear that a bus has not been turned off because there is not the usual engine noise.

Post-Deployment Considerations

Once ZEVs have been deployed, agencies will transition to conducting maintenance and tracking key performance indicators (KPI). Like operations, maintenance for zero-emission vehicles has key differences from that of ICE vehicles. Key performance indicators are used to monitor the performance, efficiency, environmental benefits, and costs associated with zero- emission vehicles and on-site green energy systems.

Maintenance

Bus Maintenance

Zero-emission bus components include fewer moving parts than internal combustion engines, which in general leads to less preventive maintenance required for ZEBs. Maintenance data from U.S. ZEB deployments are still being collected and analyzed, so it is too early to state definitively that maintenance requirements for ZEBs are lower, but examining the component parts of each bus could lead one to that reasonable conclusion.

The Federal Transit Administration (FTA), in collaboration with the Department of Energy (DOE) and the National Renewable Energy Laboratory (NREL), are working to produce initial insights into zero-emission bus maintenance compared to conventional bus maintenance. Evaluation reports of battery electric and fuel cell electric buses are available on the FTA website.

Battery health will be a new factor to consider for maintenance departments at agencies deploying ZEBs. Batteries degrade over time, which impacts the performance of the vehicles. This degradation will need to be measured and tracked. Having a plan to measure and track battery health to manage bus performance and battery warranty claims is an important part of a successful ZEB deployment.

Maintenance also requires spare parts. Transit agencies should make sure to receive a recommended spare parts list from the bus and fueling infrastructure OEMs. For spare parts that an agency does not plan to keep onsite, understanding common lead times are for those parts will be important, especially as zero-emission technologies evolve. Tracking maintenance history is one strategy that can help an agency understand future maintenance needs and provide insight into the type and number of spare parts they need to have available at any given time.

Charger Maintenance

Transit agencies deploying battery electric buses will also need to be prepared for preventative and corrective maintenance on charging infrastructure. Depot charging will mostly require minimal maintenance due to the fact that they are typically modular in design, allowing individual components to be replaced versus the whole unit. Fast charging systems usually require more periodic maintenance as they have additional components, such as cooling systems and filters, that depot stations do not (Smith & Castellano, 2015).

Green Energy System Maintenance

Required maintenance for energy generation equipment will differ depending on the technology and installation components. For ground-mounted solar, routine maintenance entails vegetation management, snow removal, and cleaning panels of dirt and debris. Roof-mounted solar arrays also require periodic cleaning and clearing along with the additional maintenance of the load- bearing roof (NREL, 2018). Due to the rotating nature of wind turbines, periodic maintenance like lubrication, oil changes, and brake pad replacements will likely be necessary. (Olsen & Preus, 2015). Each agency will need to assess their green energy maintenance needs and determine whether or not current staff will be capable of operating and maintaining the green power equipment or if the agency should contract with the equipment vendor or a separate service company (U.S. Environmental Protection Agency, 2018).

Key Performance Indicators (KPIs)

Key performance indicators (KPIs) are metrics used to monitor the performance, efficiency, environmental benefits, and costs of zero-emission vehicles and on-site green energy systems. Not every agency will want to track the same indicators, so it is important for agency staff to determine what metrics are relevant to the success of their specific ZEB and green energy deployment.

KPIs are important for tracking the benefits and paybacks of investements in zero-emission technology, both from a cost perspective and an emissions reduction perspective. If an agency received grant money for the purchase of their zero-emission vehicles, there may be a requirement for reporting KPIs. Even if KPIs are not required, developing either monthly or quarterly reports to have on record can be beneficial to successful zero- emission technology deployments. Tracking KPIs plays an important role in determining improvements that could be made to increase effectiveness of zero-emission technology as an agency gathers data and experience with the vehicles and infrastructure.

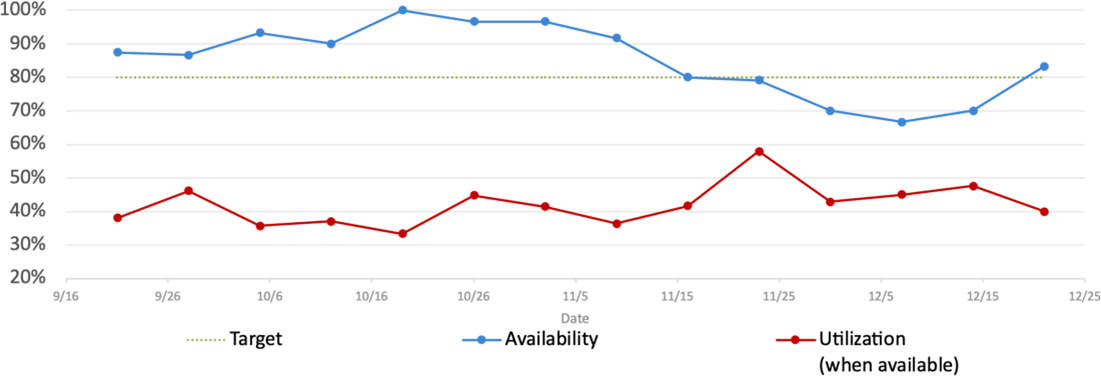

For example, utilization is a KPI that compares the number of days an agency’s vehicle was put into service to the number of days the vehicle was available for service; this KPI shows the actual usage of an agency’s zero-emission vehicle fleet compared to the possible usage. If an agency is experiencing low utilization, it could point to operational issues that the agency needs to address, such as availability of drivers trained on the zero-emission technology. By tracking this KPI and others, agencies can work to identify the root cause of operational challenges and develop a plan to address them.